- News and contacts

- Events and exhibitions

- Contact information

- FAQ

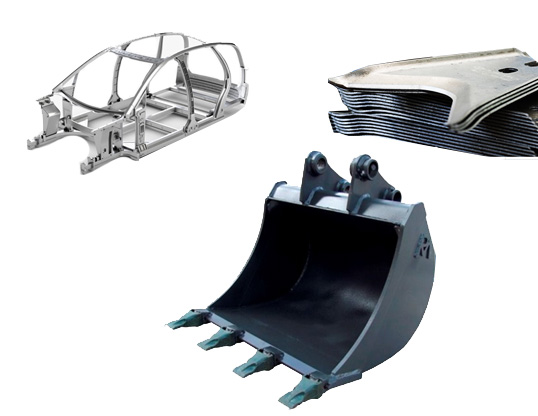

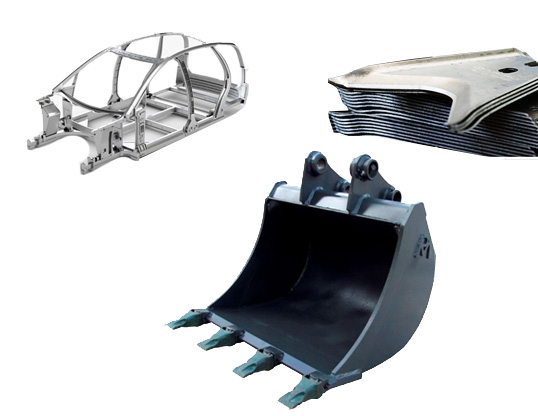

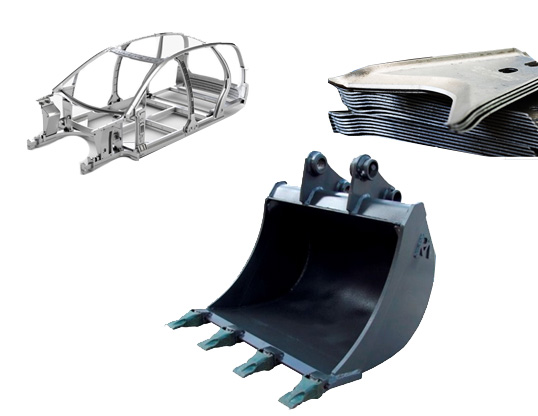

Cold Work

1.2363

UNI EN ISO 4957

This alloy is one of the cold work family, medium air hardening type tool steel. It contains chromium and molybdenum with a relatively high (1%) carbon content and is capable of deep hardening from air quench to minimize distortion. Use of die shapes, slitters, stamping, injection tools and similar application where wear resistance is important.

Heat treatment

Spherodizing Annealing

- Heat to 840-860 C and hold at minimum rate for 3 hours

- Cooling in air to 730 C then 760-770 C and hold 15 hours

- Furnace cooling

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 650-650 C hold for 1 hour per inch

Hardening

- Preheat to 600-700 C

- Austenitizing at 950-980 C in air

- Cooling in oil, thermal bath

- Quenched hardness: 63-65 HRC

Tempering

- Tempering must be carried out after hardening according to hardness requirements at 180-200 C

- Cooling in air

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

|---|---|---|---|---|---|

| X100CrMoV5 | 1.2363 | ~A2 |

|

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V | P+S |

| 0.95 | 0.40 | 0.10 | 4.80 | 0.90 |

|

0.15 | |

| 1.05 | 0.80 | 0.40 | 5.50 | 1.20 |

|

0.35 | <0.030 |

Critical points

|

Ac1

|

Ms |

|

780 C |

180 C |

1.2510

UNI EN ISO 4957

Medium alloyed cold work steel with good hardening capacity, high wear resistance, dimensionally stable during heat treatment. Its applications are cutting and punching tools, shear knives, thead rolling tools, measuring instruments.

Heat treatment

Annealing

- Heat to 740-770 C

- Furnace cooling

Stess relieving

- Heat to 600-650 C

Hardening

- Austenitizing at 790-820 C

- Cooling in oil or hot bath

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

|

|

1.2510 | 95MnWCr5 | ~O1 |

|

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V | W |

| 0.90 | 1.05 | 0.10 | 0.40 |

|

|

0.05 | 0.40 |

| 1.00 | 1.35 | 0.40 | 0.65 |

|

|

0.20 | 0.70 |

Critical points

|

Ac1

|

755 C |

| Ms | 255 C |

1.2842

UNI EN ISO 4957

Fairly good toughness and good wear resistance. The chemical composition of this steel permits fairly simple in service heat treatment (low hardening temperature with therefore limited distortion). Main applications are taps, shear knives, moulds for plastic materials, gauges.

Tempering

- Tempering must be carried out in the range 150-250 C at least 2 hours according to hardness requirements and operating conditions

- Cooling in still air

- To achieve maximum stability with tempering at the lower temperature limit, tempering must be repeated several times (at least twice) for long periods

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

| 90MnVCr8KU | 1.2842 | 90MnCrV8 | 90MV8 | O2 | BO2 |

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V |

| 0.85 | 1.90 | 0.10 | 0.20 |

|

|

0.05 |

| 0.95 | 2.10 | 0.40 | 0.50 |

|

|

0.15 |

Critical points

|

Ac1

|

730 C |

| Ms | 200 C |

Supply conditions

Annealed HB < 229

Heat treatment

Isothermal annealing

- Heat to 780 C, hold at temperature for 1/2 h to 1 h

- Furnace cooling to 690 C and hold at temperature for at least 6 hours

- Cool by 10 C/h to 650 C

- Cooling in air

- Maximum hardness 220 HB

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 600-650 C hold for 2 hours

- Furnace cooling to 300-350 C

- Cooling in air

Hardening

- Preheat to 350-450 C

- Heat to hardening temperature 760-820 C and hold at temperature

- Cooling in oil

- Quenched surface hardness: 63-65 HRC

The average hardness values that can be obtained with hardening in oil in the range 760-820 C are indicated below:

- 760 C 63 HRC

- 780 C 64 HRC

- 800 C 65 HRC

- 820 C 65 HRC

And the average hardness values and hardness penetration in oil from 800-820 C:

| mm |

40 |

50 | 60 | 70 |

| HRC surface | 65 | 65 | 64 | 64 |

| HRC 1/2 radius | 64 | 64 | 63 | 58 |

| HRC center | 64 | 63 | 62 | 52 |