- News and contacts

- Events and exhibitions

- Contact information

- FAQ

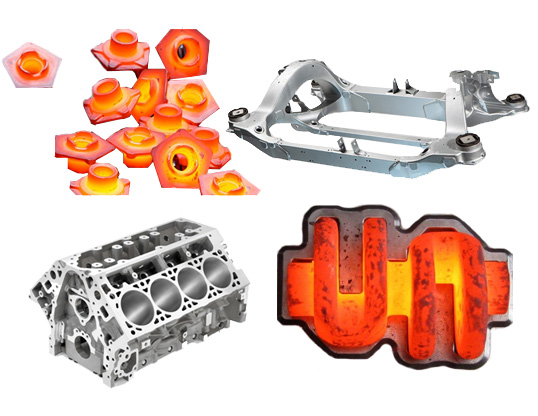

Hot Work

1.2343

UNI EN ISO 4957

Steel with high level wear properties associated with insensitivity to thermal fatigue: this steel can be air hardened which makes it possible to reduce distorsions caused by heat treatment.

Amongst the properties of this steel, it is worth remembering that it also possesses excellent toughness and is therefore suitable for use in particularly severe operating condition.

This steel is used to construct:

- dies for the pressure casting of light alloys

- moulds for plastic materials

- dies for friction and mechanical presses for hot forming of steels, brass, aluminum and its alloys

- dies for extrusion aluminum

- hot work shear blades

To raise the duration of the equipments we remember that this steel can be submitted to surface hardening thermo chemical treatments on the tools as nitrided (ion - saline - gaseous).

Before machining, the tools must be preheated to a temperature range of between 250 - 300 °C.

Supply conditions

Annealed HB max 230

Heat treatment

Isothermal annealing

- Heat to 880 C, hold at temperature for 1/2 h to 1h

- Furnace cooling to 780 C and hold at temperature for at least 5 hours

- Cool by 10 C/h to 750 C

- Cooling in air

- Maximum hardness 230 HB

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 650-700 C for 4-6 h Furnace cooling to 300-350 C

- Cooling in air

Hardening

- Initial preheating to 350-450 C

- Second preheating to 750-850 C

- Heat to hardening temperature in the range 1000-1030 C and hold at temperature

- Cooling in air

- Quenched hardness: 52-56 HRC

Tempering

- In the range 556-635 C for at least 3h according to hardness requirement and condition use

- Cooling in still air

- Tempering must be repeated a second time at temperature equal to or 20 C lower than previous

- Before tempering the parts must be preheated to 200-300 C

Comparable standards

| UNI | W.Nr | DIN | AFNOR | AISI/SAE | BS |

|---|---|---|---|---|---|

| X37CrMoV51KU | 1.2343 | ~X38CrMoV5.1 | Z38CDV5 | ~H11 | ~BH11 |

Chemical analysis

| C | Mn | Si | Cr | Mo | Ni | V | P+S |

|---|---|---|---|---|---|---|---|

| 0.36 | 0.30 | 0.90 | 4.80 | 1.10 | 0.25 | ||

| 0.42 | 0.50 | 1.20 | 5.50 | 1.40 | 0.50 | 0.015 |

Critical points

| Ac1 | Ms |

|---|---|

| 840 C | 310 C |

1.2344

UNI EN ISO 4957

Steel suitable for air hardening. It is characterized by fairly good dimensional stability during heat treatment. It maintains high wear resistance up to temperatures of around 600 °C.

This steel also possesses excellent toughness and high level insensitivity to thermal shock and thermal fatigue. A nitriding type surface treatment can be carried out on this steel to increase the service life of the tooling.

Main applications:

- dies for the pressure casting of light alloys

- tooling for the extrusion of light alloys and steels

- hot work shear blades

- rolls for profiling tools (welding area)

The tools should be preheated to temperatures in the range 250 - 300 °C before use.

Supply conditions

Annealed HB max 230

Heat treatment

Isothermal annealing

- Heat to 880 C, hold at temperature for 1/2 h to 1h

- Furnace cooling to 780 C and hold at temperature for at least 5 hours

- Cool by 10 C/h to 750 C

- Cooling in air

- Maximum hardness 230 HB

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 650-700 C hold for 4-6 h

- Furnace cooling to 300-350 C

- Cooling in air

Hardening

- Initial preheating to 350-450 C

- Second preheating to 750-850 C

- Heat to hardening temperature in the range 1000-1050 C and hold at temperature

- Cooling in air

- Quenched hardness: 52-56 HRC

Tempering

- In the range 550-630 C for at least 3h according to hardness requirements and condition use

- Tempering must be repeated a second time at temperature equal to or 20 C lower than previous

- Before tempering the parts must be preheated to 200-300 C

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

| X40CrMoV51.1KU | 1.2341 | ~X40CrMoV51 |

|

H13 | BH13 |

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V | P+S |

| 0.37 | 0.30 | 0.90 | 4.80 | 1.20 | 0.90 | ||

| 0.43 | 0.50 | 1.20 | 5.50 | 1.50 | 1.10 | 0.015 |

Critical points

|

Ac1

|

860 C |

| Ms | 340 C |

1.2367

UNI EN ISO 4957

Steel with excellent heat properties, toughness, wear resistance, resistant to heat shock and with a good tempering strength.

Possible applications include moulds for the steel production, pipe mandrels (including water cooling), dies, insert for extrusion and moulding for ferrous materials, even for equipments with hot wear resistance.

It can be coated with processes (e.g. PVD) or it can be subject to surface hardening with the most common nitriding treatments.

Before using it is necessary to preheat the instruments at about 250 ÷ 300 °C

Supply conditions

Annealed HB max 230

Heat treatment

Isothermal annealing

- Heat to 820-850 C with hold at minimum rate for 3 hours

- Furnace cooling to about 600 C

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 650-650 C hold for 2-3 hours followed by slow furnace cooling

Hardening

- Initial preheating to 350-400 C

- Second preheating to 750-800 C

- Austenitizing at 1030-1080 C

- Cooling in air, vacuum, in oil, salts at 500-55

- According to steel shape and size

- Quenched hardness HRC 53-58 HRC

Tempering

- Tempering must be repeated at least three times after hardening with preheating to 350-400 C

- Initial tempering at about the same temperature of the secondary hardness. Second tempering useful to obtain the work hardness normally 35-40 HRC

- Third tempering at 30-40 C lower than the second one

- Cooling in the air

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

|

|

1.2367 | X38CrMoV5-3 |

|

|

|

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V | P+S |

| 0.35 | 0.30 | 0.30 | 4.80 | 2.70 | 0.40 | ||

| 0.43 | 0.50 | 0.50 | 5.20 | 3.20 | 0.60 | 0.015 |

Critical points

|

Ac1

|

820 C |

| Ms | 290 C |

1.2714

UNI EN ISO 4957

Ni - Cr - Mo steel characterized by high level hardenability and toughness, good resistance to repeated shocks, fairly good insensitivity to thermal shocks and good wear resistance.

Main applications:

- blocks for dies, hammers and pile drivers

- rams for power hammers

- hot mill rolls

- very hard cold work dies and punches

It is advisable to use the blocks for dies treated at various hardness limits according to the etching depth complying with the indications given below.

|

Etching depth (mm) |

HRC |

R (N/mm²) |

|

20 |

39 ÷ 43 |

1200/1350 |

|

50 |

36 ÷ 42 |

1100/1320 |

|

100 |

32 ÷ 38 |

980/1170 |

Before starting machining, preheat the tools to temperatures between 250 - 300 °C.

Main applications:

- blocks for dies, hammers and pile drivers

- rams for power hammers

- hot mill rolls

- very hard cold work dies and punches

It is advisable to use blocks for dies treated at various hardness limits according to the etching complying with the indicators given below.

|

Etching depth (mm)

|

HRC |

R (N/mm) |

| 20 | 39-49 | 1200/1350 |

| 50 | 36-42 | 1100/1320 |

| 100 | 32-38 | 980/1170 |

Before starting machining, preheat the tools to tempertures between 250-300 C

Comparable standards

|

UNI

|

W.Nr |

DIN | AFNOR | AISI/SAE | BS |

| 56NiCrMoV7KU | 1.2714 | 56NiCrMoV7 | ~55NCD07-05 | ~L6 | ~224 |

Chemical analysis

|

C

|

Mn |

Si | Cr | Mo | Ni | V | P+S |

| 0.50 | 0.65 | 0.10 | 1.00 | 0.45 | 1.50 | 0.07 | |

| 0.60 | 0.95 | 0.40 | 1.20 | 0.55 | 1.80 | 0.12 | 0.030 |

Critical points

|

Ac1

|

740 C |

| Ms | 260 C |

Supply conditions

Annealed HB max 240

Hardened and tempered HB 370-415 1250-1400 N/mm

Hardened and tempered HB 320-370 1100-1250 N/mm

Heat treatment

Isothermal annealing

- Heat to 800 C, hold at temperature for 1/2 h to 1 h

- Furnace cooling to 670 C and hold at temperature for at least 10 hours

- Cool by 10 C/h to 630 C

- Cooling in air

- Maximum hardness 240 HB

Stess relieving

- To be carried out after machining and before the final heat treatment

- Heat to 650-650 C hold for 4-6 hours

- Cooling in furnace to 300-350 C

- Cooling in air

Hardening

- Initial preheating to 350-450 C

- Second preheating to 650-750 C

- Heat to hardening temperature 860-890 C and hold at temperature

- Cooling in hot oil (40C) oil quenched hardness: 54-59 HRC

- Cooling in ventilator air (for parts <200 mm)

- Hardness that can be obtained after hardening in air can be found in the diagrams

- The average hardness values that can be obtained with hardening in oil in the range 840-920 C are given below:

| C |

840 |

860 | 880 | 900 | 920 |

| HRC | 57 | 58 | 59 | 59.5 | 60 |

Tempering

- Tempering must be carried out within one hour from hardening (warm part) in 550-630 C for 4-6 hours according to hardness requirements, the dimension of the parts and opeating conditions

- Cooling in still air

- Tempering must be repeated a second time at temperature equal to 20 C lower than previous one

- Before tempering the parts must be preheated to 200-300 C